How To Set Pressure Switch On Well Pump

Water Pump Pressure Command Switch Aligning Basics

Water Pump Pressure Command Switch Aligning Basics

Directions to plow the big & modest adjustment nuts

- POST a QUESTION or Annotate well-nigh Setting the Water Pump Pressure level Switch and Improving Water Pressure level

InspectAPedia tolerates no conflicts of involvement. We have no human relationship with advertisers, products, or services discussed at this website.

How to adjust the pump pressure command switch using the Square-D Pumptrol™ as an instance:

This article describes how to adjust building h2o pressure by setting the water pump cutting-in and cut-out pressure on the well water pump pressure control switch. We explain which adjustment nuts to plough and in which direction to modify pump cut-in pressure or cut-our pressure settings.

This article series also includes information on how to adjust edifice municipal or community h2o force per unit area at a building.

We also provide an Article INDEX for this topic, or you can endeavour the page meridian or bottom SEARCH BOX as a quick way to observe information y'all demand.

Water Well Pump Pressure Control Switch Adjustment: how to set the h2o pump cutting-in and cut-out pressures

Here we are discussing setting the h2o pressures at which a water pump will turn on (to get more water) and off (to end pumping water from the water source into the h2o tank).

Water pumps employ a pressure command that specifies the pump cut-in (turn on) and cut-out (plough off) h2o pressures.

[Click to enlarge any image]

Watch out: SAFETY Alarm OF FATAL Stupor Risk: if y'all remove the cover of the pump pressure control switch you can go access to the two nuts that arrange the operating pressures of the water pump.

Merely watch out! There are as well live electrical contacts exposed in this area. If you touch on them, especially being nearly water pipe, there is a serious take chances of death by electrocution.

Watch what you touch, or have a professional person plumber or electrician do this job for you.

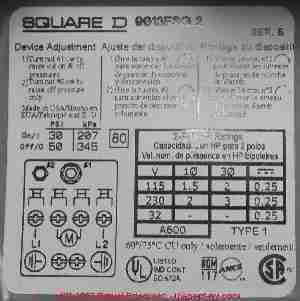

Picket out: Pump pressure control switch adjustments are summarized inside the cover of many pressure switches, as shown in our photo at left.

Which Mode to Turn the Nuts on the Water Pressure Control Switch

Complete details of what these adjustment nuts do and which mode to turn them are constitute in our separate, more than-detailed article

at H2o Force per unit area CONTROL SWITCH ADJUSTMENTS

First Diagnose the Water Pump Problem Correctly Before Messing With the Pressure Switch Control Nut Settings

Only before messing with the force per unit area command switch an accurate diagnosis of what'due south wrong might exist useful.

If the water pump apparent "short cycle" is say one-3 minutes this may be all your system can provide. If however something has inverse, and the pump used to run longer, say ii-v minutes, I doubtable loss of air in the pressure tank or an internal trouble in the tank (like a hole in the float if it'due south a "captive air" pressure tank).

The trouble of lost air in the water force per unit area tank along with how to right that condition are discussed offset

at SIGNS OF AIR LOSS.

If the "short wheel" is very short, clicking on and off, there could be a different problem with the pump command pressure switch or with a muddied, chock-full water filter if one is installed on the organisation.

Muddied water filters as a source of rapid pump on-off cycling are discussed

at CAUSES OF SHORT CYCLING.

If you want to ready up the cut-out pressure level on your pump control, while leaving the "cutting-in" downwardly where information technology is, you'll also go a longer "off" cycle, but if you prepare the cut-out force per unit area as well high, the pump volition just run forever since it can't achieve that high pressure. This is easy to figure out since if you lot set information technology too high the pump will simply go along running.

(Then plough it off electrically and gear up the cutout pressure a flake lower.) [This adjustment is only bachelor on pressure command switches that have two adjustment nuts: Range and Differential]. Details are

at WATER PRESSURE Command SWITCH ADJUSTMENTS

In sum, information technology might be possible to amend this condition past adjusting the pump control which sets the cut-in water pressure (to start the h2o pump) and the cut-out h2o pressure level (to stop the pump).

Normally this isn't going to aid with pump brusk cycling but adjusting the water pump can requite a longer on-cycle for the pump and it can increment the water organisation pressure up to a point.

If you lot inquire the pump for more pressure than it tin deliver it will simply keep running without ever reaching the cut-out pressure y'all've specified.

If your pump short-cycling behavior has recently gotten worse, don't try to prepare information technology by adjusting the pump pressures, go on to look at other problems similar loss of the air accuse in the water tank or a defective or clogged pump control or water filter.

The commodity links below explain exactly how to set the water pump pressure switch, where the adjustments are located (the large and modest nut found nether the switch comprehend), which way to turn the nuts to increment or decrease the pump cutting-in and cut-out pressures, and other pressure switch troubleshooting and repair procedures.

Which NUT the Pressure level Control Switch Does What? Range & Differential Adjustment on a Water Pressure Control Switch

The (LARGER) RANGE Adjustment nut

The larger nut (greenish arrow) on the larger spring in the pump pressure level switch: changes cut-in AND cut-out simultaneously moving them both up (higher pressure level) or down (lower force per unit area).

This is the range adjustment nut.

[Click to enlarge whatsoever image].

It has the practical upshot of raising or lowering the operating pressure range of the switch. And then if your switch was running at twenty/forty (on at 20 psi off at xl psi), and you tighten this nut three 1/ii turns, you lot'll increase both numbers so that the switch will now operate at thirty/50 (on at 30 psi and off at 50 psi).

Usually the larger nut in the pump pressure level control switch (green arrow in our photo at left) adjusts the pump cut-on ("cut-in") AND pump cut-off pressures simultaneously. This is the left-paw jump (and nut) in our photo and is pointed-to by the dark-green arrow.

That means that whatever the gap is betwixt the cut-on pressure and the cut-off pressure level, that gap is maintained, just the entire operating range of the pump is raised or lowered.

Turning the large nut clockwise RAISES BOTH the cut-on and cutting-off pressures. Then turning the large nut clockwise shifts the whole operating pressure level range of the pump Upwardly to HIGHER pressures.

Conversely, turning the large nut counter-clockwise will lower the whole pump operating range. This is the simplest adjustment to make.

Photo (above left) courtesy of a reader.

Help in identifying the range and differential nuts

- The range nut has a larger diameter spring - this shifts the whole operating pressure, Cutting-IN / CUT-OU, upwardly or downwards

- The differential setting aligning nut is on the smaller diameter spring - this increases or decreases the deviation between CUT-IN and Cut-OUT pressures

- The differential setting nut is usually on a shorter spring - it will be "lower" or further down in the pressure control switch. You will run across this in our photograph higher up.

- Some pressure command switches accept but the range aligning nut and no differential nut.

- In modern pressure control switches both basics are typically sized to be turned with a 3/8" nut driver or socket

Upshot of Turns on the Larger Pressure Range Adjustment Nut

Here is an case of Range Nut Adjustment Settings & the Number of Turns Required, using the Foursquare-D Pumptrol Grade 9013F and G Pressure Switches as an example:

Pressure Switch Range Nut Adjustments: Range Changes vs Number of Turns of the Nut | ||

| Original Range Nut Pressure level Setting Cut-in / Cut-Out Pressure level in PSI | Number of Range Nut Clockwise Turns | New Range Nut Pressure Setting Cut-in / Cut-Out Pressure level in PSI |

| xx / 40 psi | 3 1/2 turns | xxx / fifty psi |

| twenty / twoscore psi | 8 to eight 1/2 turns | 40 / 60 psi |

| thirty / 50 psi | iii 1/two turns | 40 / 60 psi |

Notes to the table in a higher place

Adapted from : "Preventive Maintenance and Troubleshooting Guidelines for Grade 9013F and 9013G Pressure Switches" (2007), Original source: Schneider Electric U.s. 8001 Knightdale Boulevard Knightdale, NC 27545 Usa one-888-SquareD (ane-888-778-2733) www.us.SquareD.com

Schneider Electrical offers technical assistance for their Pumptrol production line: Schneider Electrical Pumptrol Product Line 8001 Knightdale Boulevard Knightdale, NC 27545-9023 electronic mail: command.support@us.schneider-electrical.com Telephone: 1-888-SquareD (ane-888-778-2733)

Lookout man out: Electric equipment should be serviced merely by qualified electrical maintenance personnel.

No responsibility is assumed by Square D [ nor past InspectApedia.com ] for any consequences arising out of the use of this material. - Pumptrol Force per unit area Switch Installation & Wiring Instructions (2010), retrieved i Apr 2022, Schneider Electrical USA 8001 Knightdale Blvd. Knightdale, NC 27545 ane-888-SquareD (1-888-778-2733) www.us.SquareD.com

PUMP Pressure level SWITCH STANDARD (PSI) SETTINGS contains instructions for restoring a typical pressure command switch to factory settings

Pump Force per unit area Switch Pumptrol™ Nut Adjustment Sequence

Picket out: Schneider Electric, the manufacturer of the Foursquare-D Pumptrol pressure command switch warns that

when adjusting the force per unit area control settings it is important to brand the adjustment in the proper sequence:

- adjust the RANGE nut Beginning,

- and then adjust the DIFFERENTIAL nut 2nd.

- Pumptrol Pressure Switch Installation & Wiring Instructions (2010), retrieved 1 April 2022, Schneider Electric USA 8001 Knightdale Blvd. Knightdale, NC 27545 1-888-SquareD (i-888-778-2733) www.us.SquareD.com

Example Pump Force per unit area Switch Adjustment Instructions from Square-D Force per unit area Control

Understanding how pump force per unit area command switches work and which way to plough which of the two nuts in the control tin can be confusing.

On a Square-D Pumptrol™ 9013FSF-2 pump pressure switch, for case, Square D tells usa that nosotros

- Turn the Large Range Nut #i (green arrow at right in our photo, the larger leap and nut) clockwise (to the correct or "downwards") to raise [both] cut-on and cutting-off pressures. This is "tightening the nut down" against the bound. ("Rightie-tightie, leftie-loosie" as Mara Gieseke says to her kids). Thank you to reader Ascension for this clarification.

In other words, adjusting the pressure level on this bound shifts the whole operating range of the switch up or down, merely keeps the departure between cutting-in and cut-out the same, whatever it happens to be (typically it's about 20 psi from the factory.)

Which Way exercise I turn the Larger Range Nut on the Pressure level Control Switch

- If you want the pump to plough ON (cutting-in) sooner, that is, at a higher water pressure level, turn the nut clockwise or "tighter". This shifts the whole operating pressure range of the pump command (and thus the h2o pump) upwardly to higher cut-in and cut-out pressures.

If you want the water pump to turn ON (cutting-in) later, that is, at a lower water pressure, turn the nut counterclockwise or "looser". This shifts the operating range to lower cutting-in and cut-out pressures.

The gap betwixt cut-in and cut-out pressures remains the same when you adjust the range nut. Information technology is the smaller differential nut that can change that gap as we explain in this commodity.

Remember to adjust the larger RANGE nut first, so adapt the smaller DIFFERNTIAL nut.

Watch out: be sure to bank check the adjustment instructions for your particular pressure control switch and to follow the manufacturer's instructions. Shown below are the instructions for a Blazon 9013-series Foursquare D Pumptrol. This detail switch was the Square-D Pumptrol 9013FSG ( for which a contact replacement kit is bachelor: Catalog No. 9998PC241). The switch label instructions say:

- Turn Nut #1 CW (clockwise or "down" or tighter) to raise cut on & off pressures.

- Plow Nut #two CW (clockwise or "down" or tighter) to heighten off force per unit area merely. - Op. Cit.

Upshot of Turning The (Smaller) Differential Aligning Nut

The smaller nut (ruddy arrow) atop the smaller spring in the pump force per unit area switch: changes the differential betwixt cutting-in and cut-out pressure level.

The smaller nut (ruddy arrow) atop the smaller spring in the pump force per unit area switch: changes the differential betwixt cutting-in and cut-out pressure level.

The the pressure differential adjustment nut (and bound) in our photos - and sketches is pointed to by the ruddy pointer.

The differential adjustment nut has the practical consequence of raising or lowering the cutting OFF pressure simply. This in effect, widens the gap or pressure differential between cut-in and cut-off pressures. Or every bit the manufacturer puts it:

Adjusting the differential changes the cut-out setting. The cut-in does not modify. - Op. Cit.

Which nut to plow in the pump pressure switch control, and which direction to turn information technology, are commonly visible on a label inside the pressure switch comprehend.

In a higher place we show photos of a common Square D water pump force per unit area command switch (Schneider Electric)

and

beneath is an example of the label with pump control adjustment details.

Which Way practise I plough the Smaller (Differential) Nut on the Force per unit area Command Switch?

...

...

Watch out: we take constitute another spider web articles whose authors are confused about this switch and who did not identify the Range Nut (the larger of the 2) and the Differential adjustment nut (the smaller) correctly.

Here we follow the force per unit area command switch manufacturer's instructions and parts identification and aligning procedures.

- Plow the Small Differential Nut #ii (red pointer in our photos & schematics above, the smaller jump and nut) clockwise to heighten the cut-out pressure.

If you want the water pump to turn OFF (cut out or cutting-off) at a higher water pressure level, turn this nut clockwise or "tighter".

If you want the h2o pump to turn OFF (cutting out or cut-off) at a lower water pressure level, plow this nut counter clockwise or "looser"

Here is why the small nut is called the "Differential"

Adjusting the force per unit area on this spring shifts just the pump cut-out pressure up (clockwise) or down (counter-clockwise).

But as readers Don Travis has pointed out, it's a flake more complicated than this.

On at least some pressure control switch models, the small-scale nut on the pressure control switch increases (decline or tighten) or decreases (turn upward or loosen) the differential between the cut-off and cut-on points on the switch.

In other words, If you leave the large nut solitary and change the smaller one, you increase the gap betwixt pump cutting-in and pump cutting-out pressures. A larger gap between cut-in (cutting on force per unit area) and cut-out (cut off force per unit area) ways you will run h2o longer in the building before the water pump is turned on.

Lookout out: After adjusting nut#2 yous may need to cheque the actual operating water pressures in your system and adjust nut#1 to exist sure that you lot are not pushing the cutting-out (upper pressure level) so high that the water pump never turns off (dangerous).

Smaller (Differential) Nut on Pressure Switch Completely Loose

Photo above: a completely-loosened differential adjustment nut on a pressure level command switch, courtesy of reader Moby.

Or in a contrary case if yous completely loosen the smaller nut #2 (differential adjustment) - as we meet in Moby's photograph above, the pump differential between cut-in pressure level and cut-out pressure is very small the water pump may curt bike on and off rapidly when water is being run in the building.

Particularly if the well pump is a submersible (hidden and silent downwardly inside the actual well) you lot may non realize that the pump motor is not shutting off.

Spotter out: This can flare-up a piping, burst a water tank, cause in-building leaks (especially at pressures over seventy psi), or burn up the well pump. You lot may be best to go out this adjustment screw lone.

In sum, the "Range" nut shifts the whole operating range of the pressure level control upwards or down, merely keeps the gap betwixt cut-in and cut-out the same.

The "Differential" nut widens or narrows the gap between the cutting-in and cut-out pressures.

But messing with the gap too shifts the operating pressure of the command so you may have to re-visit the range - or go out this nut alone.

Watch out: also, every bit the manufacturer (Schneider Electric for Square D Pumptrol wiring connections) warns:

Electrical equipment should be serviced only by qualified electrical maintenance personnel.

No responsibleness is assumed by Square D [ nor by InspectApedia.com ] for whatsoever consequences arising out of the utilise of this material. - Pumptrol Force per unit area Switch Installation & Wiring Instructions (2010), retrieved 1 April 2022, Schneider Electric United states of america 8001 Knightdale Blvd. Knightdale, NC 27545 one-888-SquareD (1-888-778-2733) www.us.SquareD.com

What if my Pressure Control Switch has Only I Adjustment Nut?

Yes. Some pump pressure control switches such as Schneider Electric'southward Square D Pumptrol™ Types FTG and FHG have but a range adjustment nut.

At that place is no differential adjustment.

Only follow the adjustment instructions for the large Nut i marked in greenish and described as RANGE nut in the article in a higher place.

How to increase the well pump cut-in pressure without setting the cut-out force per unit area too high

Reader asked: We have a well and have been experiencing intermittent low water pressure.

I checked the pump and information technology cuts in at 25 PSI and cuts off at 65 PSI. Only the diagram on the inside of the pump switch cover indicates that information technology should exist cut in at forty PSI and out at 60 PSI. It has a maximum PSI of lxxx.

How do I become the well pump to cut in at forty PSI instead of 25 PSI? I believe this would requite usa acceptable h2o pressure at all times.

According to the information on your website adjusting the mainspring will change both the cut in and cut off pressures and adjusting the differential volition adjust only the cut off force per unit area. Apparently, there is no style to adjust only the cut in pressure? Thanks for your help. - 50.W.

Respond: Here is how to modify the cut-in pressure level without pushing the cut-out pressure too loftier

A competent onsite inspection by an expert unremarkably finds additional clues that help accurately diagnose a water force per unit area or pump problem.

And your cause of inadequate water pressure might exist due to more than just the static pressure adequacy of the pump. For example, the pump'southward maximum catamenia rate in gpm could exist inadequate, or yous could accept a partly closed water valve or chock-full water pipe. Put another manner, many homes that operate betwixt 30 and fifty psi have very good water force per unit area and menses charge per unit at the fixtures.

So if you lot don't there may be another problem also the pressure switch settings.

That said, here are some things to consider:

Almost pump force per unit area controls are tricky to adjust in the way you mentioned, only you lot should be able to set the cut-in to a higher number and then suit the cut-in - cutting-out pressure differential to go on the cut-out pressure from being besides high. That will cause your well pump to turn sooner when yous start running water (and will cycle it more often, a gene in pump article of clothing).

At PUMP Pressure Command Adjustment we explain that the smaller nut on the pump control switch adjusts the differential or gap between cutting in and cut out and the larger nut raises the cut-in force per unit area (as well as cut off).

In other words you tin set the cutting in pressure higher and so narrow the differential then that the cutting-off pressure is not dangerously loftier or in a higher place what the pump can reach.

Scout out: don't run the water force per unit area control with too narrow a differential between the cut-in and cut-out or the pump may merely sit there short-cycling until you burn up the motor. If your pump is staying on for less than thirty seconds (I adopt longer), yous may exist heading for problem.

Watch out: setting the cutting-out water pressure also loftier can crusade the pump to never turn off or at high pressures you may detect leaks at fixtures. And high water force per unit area that exceeds the rated water tank pressure can burst the tank - a very dangerous event. Also make sure your pressure tank has a relief valve installed.

Finally, I suspect that afterwards you accept increased the pump cut-in or cutting-on pressure to a higher number, say thirty psi, if you will observe that this does non fix your water pressure problem.

The fact that your low water force per unit area is intermittent might in fact signal to a trouble with the well flow rate itself.

See WELL YIELD DEFINITION.

Once the well pump turns on and presuming you are running water continuously, specially if more than one fixture is running, you may encounter that your pump runs continuously until yous turn the h2o off. If this is the instance, information technology'southward non the starting water pressure level setting that is at fault, it's the pump or piping or well that is limiting the h2o flow charge per unit.

If I'm right that means that the water menses charge per unit through the arrangement, from well through pump and pipes, elbows, valves, etc. is just non enough, and further diagnosis is in social club.

Follow-up and Water Pressure Problem Solved:

Looks like I will call a plumber. I adjusted the mainspring to heighten the cut-in/cut-out range but there was no change.

The water pump switch was faulty and had to be replaced. As well the line going into the water tank was clogged and had to exist rodded out. Working fine now.

The homeowner attempted to adapt the force per unit area control switch for the water pump. When he turned the adjusting nut the water pump behavior and water pressure did non change. That observation led to calling a plumber who replaced the pressure command switch - which solved the water force per unit area problem.

Reader Q&A - also run across the FAQs series linked-to below

How to increment the h2o pump pressure level command cutting-in and cutting-out pressure

Question: I have a foursquare d control. It cuts off at 40 psi and goes down to 20 psi before it comes back on which is to low when I am using ane sprinkler

I want it to come up on at thirty psi. I can't understand how to do that looking your directions. Pls help - John five/19/11

Reply:

How to increase the water pump pressure control cut-in and cutting-out pressure:

Take a wait again at the instructions above that bespeak which nut to plow in which direction to increase the well pump cut-in pressure (that's your 20 psi number) and cut-out force per unit area (that's your 40 psi number).

Y'all should exist able to raise the cut-in pressure to 30 psi and y'all will probably want to raise the cut out pressure to l psi, provided that your pump can actually reach that number. If the pump keeps running forever even After yous have turned off the h2o, then it is non capable of reaching fifty psi and you'll have to lower that setting to avert burning upwardly the water pump.

If the instructions are however as well complicated to follow and then you would be all-time off request a plumber to modify the settings for yous. Just be certain the person you rent is familiar with well pump pressure control switches.

Question: I'd like to get the cut-on at sixty and cut-off at seventy.

I but rebuilt a Sta-Rite water pump (JBMG-41S)(2hp).

It had never been serviced and had alot of iron build-upward. The shaft had seized. Later cleaning it out and putting new seals, it was withal able to run ok then I reinstalled information technology. Then it seemed there was a problem with the pressure switch

. I cleaned out the pipes connecting to information technology and cleaned the switch itself merely I wasn't able to become to a setting that wasn't cycling too quickly. I and so looked at the air pressure level in the pressure tank.

This organisation is installed in an old vi floor apartment building. The city supply is about 45psi I wanted to get a cut-on pressure of about 55psi and a cut-off at about 75. The pressure tank (Challenger pc266r - 85 gallon) turned out to be over-charged.

I'm not certain what the pressure was at but it was over 60psi. I allow out the air until it got to around 51. Now, cut-on force per unit area was effectually 55 and the pump was staying on for around 10 minutes before it reached 70psi but even with the differential nut unscrewed all the way I couldn't get the pump to plough off at 75psi.

I finally unscrewed the main nut and the pump went off but now the cut-on pressure was slightly lower.

I'd like to get the cut-on at lx and cut-off at seventy.

Help appreciated. - Ben 4/ix/12

Reply:

Ben, please accept some other look at the details in the article above about adjusting the pump pressure level control switch. Y'all'll meet that the two adjustments (on switches that have two) do not operate independently, then changing ane can require fine tuning the other.

The larger nut shifts the whole cutting-in/cutting-out pressure range up or down, while the smaller nut changes the width of that range - the differential between cutting in and cut out.

Question: Foursquare D pressure level switch prepare thirty-fifty, can I eliminate the low pressure cutting-in?

I Have suare D switch thirty-50 lb. with low pressure close off. It causes me a lot of problem when I fill large livestock tanks,tin can I modify the switch to eliminate the depression pressure close off feature or must i supervene upon the switch. thanks - Mike Jones 8/22/11

Reply:

Mike,

I'yard not certain what problem y'all're having with the pressure control switch, and that those details might be diagnostic.

If the pump is short cycling that's usually a pressure tank problem not a switch problem.

If the switch is burning upward while staying "on" you might need to go to a two-switch system in which the Square-D switch switches on a heavy duty relay that turns on and off the pump.

Sediment in the tank won't change edifice water pressure - that's created past the pump; but sediment in the tank may be a clue to other sediment clogs throughout the plumbing arrangement.

Oof... Cheers... Since I draining the tank (when testing the air pressure in the tank, cut-in/cut-out pressure, etc.), the flow has definitely decreased. I'm thinking maybe tank sediment is to blame but could merely be an exasperation of the menstruation issue that started the investigation. Thanks again.

Normal people would telephone call that weak water pressure level merely in fact since your pump is able to pump up to 62 PSI Information technology's actually a menses problem. If the problem is the same for both hot and common cold and then in that location may be clogs in the cold supply to the building. If a hot water is significantly weaker than cold and we wait mineral scale to be the problem

Thanks very much. That is helpful. Since the full general catamenia is weak at all fixtures, information technology seems not to be valve-fixture specific unless the prior owner reduced them all (I'll check that adjacent).

More often than not, when I flush the toilet or have water running anywhere in the house, the other fixtures have specially weak menstruum. Thank you again.

Welcomed

You can get out the pressure switch where it is if that works ok for you, but so you'd set the tank air pre-charge to 38 psi.

The procedure is at H2o TANK AIR, HOW TO Add

Information technology's causing a pump to cycle on and off rapidly that is most wearing; as long as the pump has no trouble reaching the cut-off pressure then it'due south ok to use the college pressure level setting.

Only allow's don't mix pressure and catamenia; if the actual catamenia rate at fixtures is weak and so information technology could be that at that place are clogs in the piping organization or a valve partly closed, or the well flow rate could be limited.

I purchased my habitation in May and it has depression water pressure. The well's tank air pressure is currently 28psi.

Pump controls say the switch should exist set to 30psi cut-in / 50psi cut-out (pump 3/four hp); only the bodily cut-in is set to 40psi and cut-out at 62psi.

To address the low pressure, should I reduce the settings back to the thirty/50psi or increase the tank pressure to 38psi?

Would the differential (28psi tank pressure level vs cut in psi set to 40) cause low h2o pressure level? Will the switch settings existence increased by 10psi (cut-in and cutting-out) eventually cause an issue with the pump's or the tank's longevity? Thanks!

That makes me doubtable debris clogging of the pressure level control switch or the tube that feeds h2o pressure to its sensor. Supersede the switch and clean the tub or pipe.

Our residential well is possibly 700' deep. Pump control relay fix 40/lx. Usually works fine.

Trouble: Pressure estimate sometimes continues slow ascent afterward pump relay cuts out at 60psi. Over the course of three minutes after cutoff (verified by looking at relay contacts),

water pressure level reading rises to 85 psi, and is correspondingly very high at faucets. Air valve at Welltrol force per unit area tank reads 87 psi air pressure.

Possible Cause : static head pressure from standing column after pelting? Other causes? Fixes?

Kathy,

Usually when a pump will not plow off and cannot reach the cutting-off pressure level attack the pressure control switch the problem is not the switch but rather that the pump and water supply are not able to deliver that pressure. That's especially true if you lot're cut off pressure level is at a normal level of a say 40 or 50 psi.

Your comment "When I smacked the switch information technology would turn off nonetheless." suggests that the pressure control could exist droppings clogged. You lot should have that control replaced.

I am but able to speculate as I'm not on the scene possible that you are what are you lot straight exceeded the wills flow rate so the pump in fact only couldn't become enough water to send into the pressure tank to reach the cutting-off pressure. When you then exit the pump off for a time that gives your well a chance to recover and that in turn might allow the pump to operate normally. So why don't yous do an experiment letting the pump system residual for several hours or longer when it's misbehaving. Then turn information technology back on to reach a cut off pressure I suspect the problem is in your well and the well flow rate and it would merely be a waste material of ex's time and free energy to change switch.

Just replaced a 30/50 switch considering the 1 hp jet pump could not get to a higher place 37 and would not turn off. The pump, tank and piping with human foot valve are i twelvemonth former. No bug until a few days ago, would non shut off. I was manually turning the pump on and off at the breaker. I am a senior lady living alone.

When I smacked the switch it would turn off however. And then the next solar day, it fabricated it to 50 and turned off by itself. Yay! Fixed? No, a few hours later stuck at 37. My ex installed a new switch yesterday.

Adapted the tank by a couple pounds (to 28) and information technology came on at 30 and off at fifty. Just once though. Now it is dorsum to 30/37. No leaks, pressure level stable unless using h2o. Ex wants to install a xx/40 switch. I don't sympathize what this could be? Ane twenty-four hour period it pumps up to 50 and then just 37 with no stopping. This new switch doesn't turn off when I endeavour and flip the contacts either. I have to employ the breaker to turn it off. Help!

Francis

You can change the pressure control switch adjustments eze explained in the article above on this page.

Please take a await and let me know if that leaves you with any questions.

How practise y'all increase the pressure on a well pump

How do yous increase the pressure on a well pump

Robert: a h2o pressure approximate installed literally anywhere on the water supply organisation will tell y'all the h2o pressure. Note that the force per unit area reading volition vary but will be at its maximum when you are not running h2o and when the water pump has only turned itself off. Unremarkably we install such a approximate right at the water tank.

Encounter details at Water PRESSURE Judge

How practise I know what the pressure level is set at

Yes, Dick,

That's exactly right. Gear up the pressure, then, to 2 psi beneath the pump control CUT IN pressure.

i emtied my galvenized presser tank. earlier i refill information technology , do i pressure it showtime?

Thanks for the question, Cythia.

Please meet the diagnosis and repair suggestions found at

Brusk CYCLING Water PUMP

and and then don't hesitate to ask follow-upwardly questions.

Y does my to a higher place ground household jet pump keep short cycling. I merely replaced force per unit area switch. No leaks.

Rich

Nosotros need to endeavor to diagnose what's incorrect earlier proposing a set up. I don't know whether the problem is with your poop is damaged and tin can't reach college pressure or there'southward a leak in well pipage or the will flow rate since they tin't accommodate the pump. In the ARTICLE Alphabetize you'd discover these two articles that will help you diagnose and fix a force per unit area switch that can't reach the cut-off force per unit area that you have prepare to fifty psi.

- H2o PRESSURE Tabular array ii: PUMP RUNS, WEAK or NO Water Pressure level

- WATER PRESSURE TABLE 3: PUMP RUNS, NO WATER or Insufficient Water

Take a look at those diagnostics for a pump that cannot reach the cut-off pressure. Tell me what you think and go on to post questions or progress and we will take information technology from at that place.

Accept a new square d well force per unit area switch 40/60 and and a sta rite snd 3/4 hp pump. Cannot become force per unit area over 50 lbs cutoff and cutting in at 35. Moved the big but two turns clockwise and pump won't shut off untill I turn big nut back two turns. Replaced human foot valve ii years ago and that's when my force per unit area drop to 50 lbs. Gauge holds steady so I don't call up I have a leak. How can I go more pressure level?

Anon

You wouldn't use a "Reducing valve" at the pump; normally the h2o pressure boosting pump either has an adjustable output pressure correct at the pump or if it'due south a conventional pump and pressure tank the pump force per unit area control switch sets the force per unit area range by turning the pump on and off appropriately.

The water pressure in our firm is weak, I need an extra force per unit area Im thinking of buying a pump, just some other problem is besides high pressure level. Can i connect a reducing valve to the pump? Is in that location an upshot int the pump?

Water pressure level reducing valve can be continued to a h2o pump? Can it damaged the pump?

Weird issue, water pressure was fairly constant in house until 5-half dozen days ago, and then sudden driblet off. Had someone out to repair and said the galvanized line to the pressure switch was chock-full and was replaced. Water is back to normal except in the morning when pressure is again low and nosotros used to be able to shower and run the laundry car at the same time but now the shower pressure level is too depression when the washer is running.

Also seems to be low later on no water usage overnight merely and then improves after nosotros beginning using it. Any tips or advice?

Why the pump doesn't cutting off?

Perhaps clogged pipes or shower heads

I take a well water at my dwelling house. The pressure level in the tank reads 50 when pump cuts out and 30 when starts. It seems to work fine. But there is very low pressure in my showers in both bathrooms. What is the trouble?

Question: Genesis pressure command switch pressure level adjustment

I've got a switch that seems to have been made by Genesis (simply no maker data, no function number, etc.; that's just the proper noun on the encompass box) of my Panamanian pressurized residential system.

Turn-on was around 19psi by the gauge, off at 45 (which drifts down to 41.5 during the first minute after the pump shuts off, then stays stable).

I tried both adjustment nuts, separately, and while a one-half-turn clockwise will go the left-hand nut (the big Range one) took the cutoff to 49psi, nothing seems to motility the plow-on pressure up.

I'd like to be able to bring that upwardly to almost 25psi, because much below this the boiler (pass-thru, seven liter tank within) won't kick on and stay on.

Was a half to a full turn only not plenty to get that switch's attention? Information technology's only a two yr old switch. - notonyourtintype - 7/nineteen/eleven

Reply:

Noton... I'd like to meet some sharp photos of y our switch - you lot tin send pix to the CONTACT link found at the left or bottom of our website pages.

The operating pressure range you describe is common: roughly on at twenty off at forty psi.

The judge behavior you depict could be due to a partial blockage of the gauge mounting pipe or approximate bottom with debris, slowing down the passage of pressurized h2o into and out of the guess lesser.

Try tapping the estimate too - remember these h2o pressure level gauges are not precise.

Most water pressure gauges work most the same style - if yours looks like the examples I show above, you should be able to review and follow the force per unit area gauge adjustment procedures constitute in a higher place on this folio.

Turning the nut just a half turn, depending on which nut, may not have registered, or it may take some borer or a few pump cycles for you to see the effect.

On 2022-05-05 by Inspectapedia Com Moderator - pump cuts out only won't cutting in again

@Ed,

That actually sounds to me similar a corroded or damaged pressure control switch. Have you tried replacing information technology?

My pump runs and cots out okay just will then not cut in over again. If you unplug the pump then open the cover and press the contacts together then reconnect information technology to the electricity then pum runs until it cuts out just doesn't cut in once more. what does this mean?

I raised my well pumps water pressure but at present the pump won't shut off. Help.

On 2022-x-31 past inspectapedia.com.moderator - how to restore pressure command switch to factory settings

thanks for your answer, but the mill setting is xl-threescore, but I am unable to achieve this. Can either get xx-50, or 30-threescore, cause the gap won't alter with the differential nut setting.

@philip hannem,

It probably means that at least i of the two aligning basics on the pressure level command switch has been loosened or tightened then far that the other nut has no upshot on the switch behaviour. I'd return the switch to factory settings and kickoff over.

what does it mean if the differential nut does not enhance or lower the high presure cut off and the gap stays the same?

In my case I noticed decreased presure in the shower, and saw that the departure betwixt the two readings was near thirty instead of twenty, so I attempted to turn the minor nut to the left to bring the gap near 20, and and then was going to heighten the over all preasure with the big nut if it still was not adaquate, just the small nut does non change the cut out preasure no affair how far I turn it.

The big nut, even so, does do exactly what it is supposed to, raises both at the same time. This however did non solve my problem. I checked and adapted the preasure tank preasure, and zip has changed.

@GERALD,

The article above explains how to brand pressure control switch adjustments more completely and accurately than if I try to make it up again here.

However I advise you not to try to gear up your pump to the numbers that yous give as having such a modest difference between cut in and cut out ways with your pump will short-wheel so chop-chop that you may fire up the pump motor.

Is it possible for you lot to install a larger water pressure level tank? That would help the trouble that you describe.

My pump is set at 20-twoscore cut-in/cut-off and it is only a 24 liter tank. (I am in the mountains of Panama) Considering of this the force per unit area at the shower is up and downwardly and not consequent. And with a indicate of use heater, the temperature is not consequent.

How to I adapt the range to 28-forty?

I tried resetting the pressure switch and yet low pressure in the house. What do i practice.

On 2022-07-17 by inspectapedia.com.moderator (mod) - steps for checking why new pressure switch doesn't piece of work

@Frank McDaniel,

If you know how to do safe electrical piece of work (else you tin be shocked or killed)

- bank check for ability delivered to the control

- check that the control is wired according to the manufacturer's instructions

- bank check that system pressure has been relieved (run water) until the pressure gauge shows you at or below the pressure level command Cut-IN pressure

I put a new 1 on and it'southward not working

On 2022-06-05 by mak.church (mod) - how to change pressure control switch for private or municipal water supply

@John Opoku Agyemang,

You are on a folio discussing adjusting water pump pressure past irresolute the settings on the pressure level control switch - IF your water supply is by pump and well-water OR if your building uses a pressure booster pump controlled past a switch like the ones shown above, then you're in the correct place. Read the above and if it'due south unclear, please allow u.s. know.

Just

If your h2o is supplied by a municipal or community supply, that is, non by private well or pressure pump, and then you will desire to read

H2o PRESSURE REGULATOR Adjustment

Please, if you the pressure is 6 bar and you want to reduce to 3 bar what tin can i do to get iii bar?

No Al

Loosening the range nut brings the force per unit area control switch operating range down to lower pressures (see the tabular array to a higher place on this page).

To bring the pressure RANGE UP you would tighten the range nut - that lifts both cut-in and cut-out to a college pressure level.

If I wanted to have my pump cut in at a college pressure and cut off and the current pressure level, I assume that I would 1) loosen the pocket-size range nut to bring down the range and and then ii) tighten the big nut to bring the cut off to the current pressure?

Pat:

Some submersible pumps run on higher voltage powered by a separate control relay. The pressure control switch turns the relay on and off, and the relay operates the pump.

Manifestly I don't know what you've got installed. Is there a second relay box?

Watch out: if yous're not experienced with electric testing yous could be shocked or killed - take care.

The air bleeding procedure you describe could mean that the pump itself is air leap or has low water in the well or that there is a snifter valve assembly that's not working properly on your well.

Take a look at SNIFTER VALVES in the ARTICLE Alphabetize.

As of yesterday after I turned off irrigation that the well would run-on, not pressurizing the pressure level tank to 60psi and then cutting out.

I have a 250' deep well, I practise not know which brand pump is below, it is a 3 wire 240vac type pump though.

When I accept the AC breaker closed for the well, and take power readings within the well pump controller, the primary voltage coming from the pressure switch is 248vac, yet, when I take a voltage reading at Red & Black of the well pump motor, the voltage is 320vac?!

At this point, I have made sure there are no house side leaks.

Each fourth dimension I restore power to the well, I take to depress the Schrader valve (on the check valve on the pump inlet side of the bank check valve) until air ceases and water begins squirting.

When I have the Air conditioning breaker opened (no power to well) and identify my ear to the 1.25" pipage coming up from the well head, I hear a hiss, and likewise during this scenario, the pressure at the pressure tank slowly drops downwardly ... would this be the check valve just up=line from the indicate I am listening to the pipe?

Thank you

Comment: clarifying the differential nut adjustment range

7 March 2022 Andy said:

Near the top of this commodity, it says: 'Watch out! If you lot loosen this nut too much you can fix the cut-off pressure level below the cut-on pressure and the pump will plow on and run forever (or until it burns up.)'

This doesn't brand sense. If you back the differential nut off 'too much', all that ways is that the differential volition be at its minimum which might cause short cycling. Shortcycling at the well pump is of course damaging too, merely the pump tin't fail to shut off if the main spring is set anywhere near the standard and all other things are normal. What am I not getting here?

Reply:

Cheers Andy, you're right and nosotros deleted the confusing text. Nosotros appreciate your conscientious heart and tin can utilise all the editing help nosotros can get.

Afterward adjusting nut #2, the smaller nut that in virtually of these controls adjusts the differential betwixt cut-in and cutting-out we kept this warning

Watch out: After adjusting nut #2 you may demand to check the actual operating water pressures in your system and adjust nut #1 to be sure that you are non pushing the cut-out (upper pressure) and then high that the water pump never turns off (dangerous).

As your comment points out, an additional caveat could be added: don't set up the differential betwixt cut-in and cut-out as well shut or the pump volition curt-bicycle.

A different error would be to fix the Nut #1, the larger adjustment, cutting-out pressure too loftier. That'due south a common mistake that some folks make in trying to go the highest water pressure possible in their building. The result could indeed be a pump that never shuts off and that burns up.

On 2022-09-21 - past (mod) - how to get the pressure switch dorsum to manufactory settings

John

You may need to render the switch to original manufacturing plant settings as, speaking from experience, it's easy to turn the large or small aligning nuts until yous lose track of where you started and the switch will not work properly.

At PUMP Pressure level Control ADJUSTMENT we explain that

the smaller nut on the pump control switch adjusts the differential or gap between cut in and cutting out

and

the larger nut raises the cut-in pressure (as well as cut off).

The 25/55 settings you seek might be outside the range adjusted by the smaller nut. Just you tin can try adjusting the switch as follows.

I would try going back to the original settings given in a table in a higher place on this page.

If that takes you to a twenty/twoscore psi range then yous tin plow the larger "range nut" virtually ane 1/2 turns clockwise to make the new operating range 25/45 CUT-IN/CUT-OUT psi.

Watch out: Take intendance that if you lot gear up the CUT OUT college than your pump and well tin evangelize then the pump volition not shut off (and you'll burn it upwards)

Next y'all tin adjust the smaller "Differential" nut CLOCKWISE (Tighter) to crusade the pump to turn OFF at a college pressure. So tightening the small nut (Non loosening information technology) should raise the CUT-OFF pressure - you might go that upward to 55 psi.

Nosotros have a Square D pressure switch on our well pump. Cut in is 25 PSI. and cut off is 55 PSI. At this time, the nut on the small leap backed all the style off. Cut in @ 30 PSI is platonic, just I do not want to heighten the Cut off PSI anymore which is what happens when I turn down the big spring. Any thoughts? Thank you.

Mike,

Don't feel bad most having fouled up your pressure control switch and having trouble getting back to the original factory settings. It's a trouble that about of us who have worked on any volume of equipment accept encountered at once or another, including me.

Have a wait in the article higher up and below this article subheading

Issue of Nut Turns on Range Adjustment

Y'all will find a table that gives the typical original or manufactory settings or number of turns on the adjustment screws so that should help y'all out. Let me know.

Hi all! I've got a problem with the differential. Is in that location an piece of cake style to get that back to a 20 spread? I was fiddling for far as well long with it trying to increase my water force per unit area. At present, the differential is backed all the way off the spring. I tin can't get information technology dorsum to the manufacturing plant setting 40-60. Thanks!

Eric

A place to start is by turning off the h2o between the pump and tank and the residuum of the edifice. If you're sure that valve is closed in the organisation continues to lose pressure than the leak is either in the pump itself or in the well pipage between building and well or in the well itself, such equally a bad human foot neglect

My problem is i can not agree water pressure level which leads me to think theres a leak..i have replaced pressure level switch assault 30-50..new gauge and pressure release valve while i was at it...my pump cycles thru pressure drops to 30 kicks on shuts off at l..just doesnt stay on 50..check everywhere for leaks can not notice one...how do i determine if something downwardly in the well itself is leaking?

Well yep I've snarled up a switch or two back in the day, besides, Scott.

It can be disruptive because yous have 2 adjustment basics but the spring tensions interact.

I would effort going back to the original settings given in a table to a higher place on this folio.

If the pump is turning on at but under fifty psi that sounds considerably as well loftier to me; Normal cut-in is either 20 psi on a 20/40 switch or 30 psi on a 30/50 switch from the factory.

The tank pre-charge air pressure level - with the pump off and all pressure relieved at a water tap - would be around 2 psi beneath the cutting-in pressure.

I accept a Well-Xtrol WX203 tank and a PumpTrol switch model 9013FSG2. About xx yrs. old. Submersible pump. Everything professionally installed by well driller. Gear up for 20-forty psi functioning. Take a brusk-cycling problem.

First checked air pressure in an empty tank. That was zero. Estimate a boring leak over xx years. No water at Schrader valve so no float leak, correct?

Pressurized the tank when empty to 38 psi. Now trying to become a twenty psi operating range 40-sixty psi between cycles to no avail. The issues:

1) tall nut is set to sixty psi. Brusque nut is every bit low as information technology can go, No spring tension at all and still tin can't get back to 40 psi. It cycles on a footling less than l psi and then still accept a short cycle and a 10 psi operating range.

2) I close power and house supply off to drain tank once again and check my charge to meet if information technology remains constant. Information technology doesn't. After drained it reads 55 psi when I originally charged it to 38 psi. Where did the actress pressure/air come from?

3) When I drain the tank to perform a pressure bank check, I get trivial if any water from the tank, which would explain why my bicycle sucks. Geez, the 203 is pretty big tank. Why footling if whatever water in at that place?

4) When I drain water from the tank after everything shut off, the water pressure level judge but drops to aught with no flow. I would expect a gradual drop on the garage as water flows out. Not so.

I'm running out of ideas. Tempted to replace the switch. But I don't come across how that is going to put more water in the tank.

Karl at that place are some excellent diagnostics found in the Commodity INDEX near the end of the article on this page - on AIR Belch AT FIXTURES

Hello, I seem to have lots of air in my h2o pump system and it's not a big organisation and I've check everywhere for a possible leak and in that location isn't one to be found. Pressure tank reads the proper pressure as well. Would adjusting the nuts on the pressure switch assist with this or is there something else wrong with my system?

Recently nosotros had our pipes freeze and this problem occurred afterwards removing the ice and information technology took 3 days to get the pump up and running again. I'chiliad afraid to tamper with information technology likewise much seeing how nosotros went 3 days with no water at all already but the air is getting worse and I find it looses pressure and kicks in more than often when no water is even running

Phem

A power outage can damage a pressure switch, pump wiring, or even the pump itself.

Your electrician will check offset to run across if you have a 240V pump that'south getting just 120V or that'due south getting low voltage.

That's followed by some current depict (amps) checks to see if the pump motor is shot - which as I say can happen from a power surge.

Don't carp trying to change the pressure switch settings. Those are adaptable screws or basics that would NOT have been changed past a power outage nor surge.

You lot could try first replacing the entire force per unit area control switch AND making sure that there is no clog in the tube or piping that communicates water pressure level to the switch. But frankly if the pump is heating up it sounds every bit if either the pump is running dry (no h2o, causing harm) or it's already damaged.

my pump was working well before the contempo ability outage, when the ability returned the following day the cutting in and cut out settings on the pump had changed and instead they are mode lower such that the water literally stops flowing in the house before the pump kicks in.

Also the pump runs longer and has started heating upwardly. delight advise earlier i start tempering with the settings which i believe should be ok.

Pumptrol Square "D" Force per unit area Switch;

Cuts on at 20 and off at fourscore. The cut-off is OK only the cutting-on needs to be twoscore or 50.

How do I fix thlis....? ick...

...

Continue reading at PUMP PRESSURE SWITCH STANDARD (PSI) SETTINGS or select a topic from the closely-related articles below, or see the complete Commodity INDEX.

Or see Pressure level SWITCH NUT Aligning FAQs - questions & answers about this article

Or come across WATER PUMP Force per unit area Control Adjustment FAQs - general questions virtually the force per unit area control switch and its function

Or encounter these

Recommended Articles

- WATER Pressure level Command SWITCH ADJUSTMENTS - home for water pump pressure control switch

- Water PUMP Force per unit area SWITCH DIFFERENTIAL NUT ADJUSTMENT

- WATER PUMP Force per unit area SWITCH RANGE ADJUSTMENTS

- WATER PUMP Force per unit area SWITCH SAFETY

- H2o PUMP PRESSURE SWITCH SETTINGS

- H2o PUMP PUMP PRESSURE SWITCH STANDARD (PSI) SETTINGS

- Water PUMP Pressure level SWITCH MAXIMUM Pressure level SETTING

- WATER PUMP PRESSURE SWITCH INSTALL / REPLACE

- Water PUMP PRESSURE SWITCH INSTALLATION MANUALS

- Water PUMP PRESSURE SWITCH LEAKS

- WATER PUMP PRESSURE SWITCH LOCATION

- WATER PUMP PRESSURE SWITCH NOISES

- H2o PUMP Force per unit area SWITCH REPAIRS

- H2o PUMP Force per unit area SWITCH SAFETY

- WATER PUMP SHORT CYCLING - home

- H2o PUMP Short CYCLING - pump turns on and off to apace

- H2o PUMP WON'T Kickoff - no water pressure level

- WATER PUMP WONT Stop RUNNING - pump simply keeps running

- Water TANK AIR Force per unit area ADJUSTMENT

Suggested citation for this spider web folio

WATER PRESSURE CONTROL SWITCH ADJUSTMENTS at AuditApedia.com - online encyclopedia of edifice & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

Alphabetize to RELATED ARTICLES: ARTICLE Alphabetize to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

...

Ask a Question or Search InspectApedia

Endeavour the search box just below, or if you prefer, post a question or comment in the Comments box below and we will answer promptly.

Search the InspectApedia website

Notation: appearance of your Comment below may exist delayed: if your comment contains an image, web link, or text that looks to the software as if it might be a web link, your posting volition announced after it has been canonical by a moderator. Apologies for the delay. Our Comment Box is provided by Countable Spider web Productions countable.ca

Technical Reviewers & References

Click to Show or Hide Citations & References

Source: https://inspectapedia.com/water/Pressure_Switch_Nut_Adjust.php

0 Response to "How To Set Pressure Switch On Well Pump"

Post a Comment